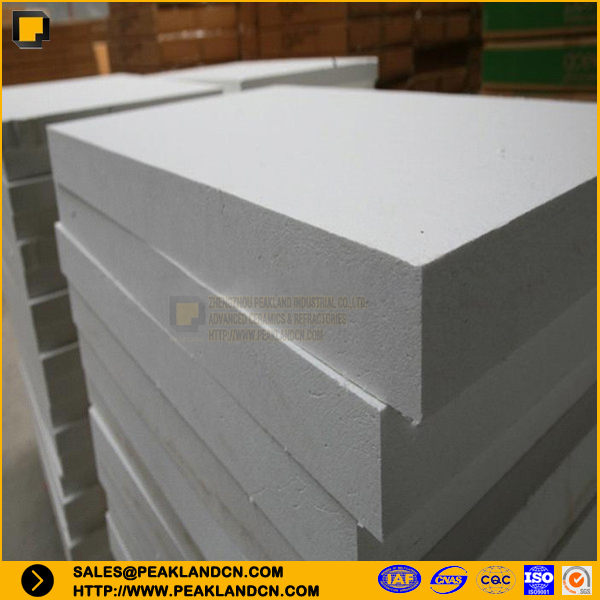

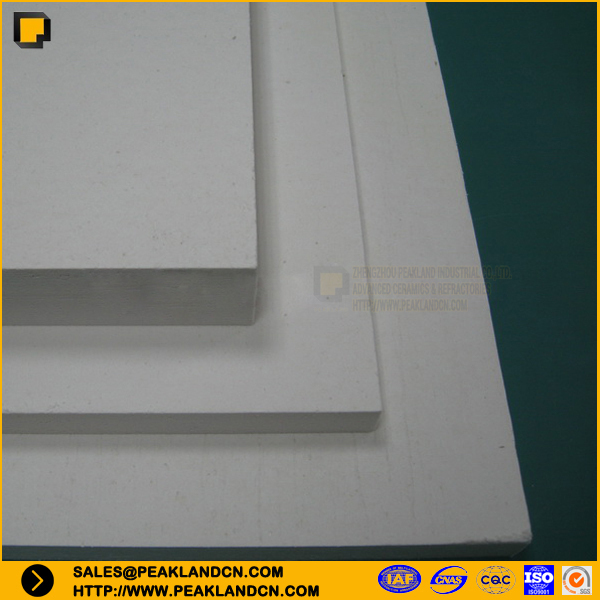

Aluminosilicate Ceramic Fiber Board

1. Properties:

- Low heat storage and low thermal conductivity;

- High compression strength;

- Non –fragile materials and good toughness;

- Accurate dimension and good plainness

- Structure homogeneity and easy machining;

- Continual production, even fiber with stable property;

- Excellent heat stability and thermal shock resistance

- Low impurity, even bulk density and thickness

- Excellent mechanical strength and structural strength

- Smooth surface and Lightweight

- Resistant airspeed eroding

- High plasticity to make complex shape

- Light weight and easy to cut or install

- Good erosion resistance

- Shorter heat up and cool down time

2. Specifications:

| Item | Common | Standard | High Pure | High Al | Zr-Al | |

| Classification temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

| Working temperature (°C) | ≤1000 | 1050 | 1100 | 1200 | 1350 | |

| Color | White | Pure White | Pure White | Pure White | Pure White | |

| Density (kg/m3) | 260 320 | 260 320 | 260 320 | 260 320 | 260 320 | |

| Shrinkage on heating (%) (Temperature 24 hours, density as 320kg/m3) | -4 (1000°C) | -3 (1000°C) | -3 (1100°C) | -3 (1200°C) | -3 (1350°C) | |

| Thermal conductivity of various temperatures (w/m.k) (density 285kg/m3) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | |

| Compressive strength (Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

| AL2O3+SIO2 | 96 | 97 | 99 | 99 | – | |

| AL2O3+SIO2+ZrO2 | – | – | – | – | 99 | |

| ZrO2 | – | – | – | – | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

| Dimensions (mm) | Common Specifications: 1000x600x10mm-50mm/1200x1000x20-50mm 1200x500x10-50mm/1000x600x10-50mm 900x600x10-50mm/600x400x10-50mm Other specifications can be available. | |||||

3. Applications:

Cement building industry, kiln back lining-thermal insulation;

High temperature reaction, heating device-wall lining and back linings

Ceramic industry-lining of various kilns for thermal insulation;

Petrochemical and metallurgy industries- back linings, wall linings, and linings-thremal insulation;

Glass kiln lining and back lining thermal insulation;

Heat treatment furnace kiln back lining thermal insulation;

Aluminum factories-reduction cell firebricks back linings;

Material

PEAKLAND Aluminosilicate Ceramic Fiber Bulk.

Lead time

Lead time: usually 20-25 days after payment received.

Packaging

Packaging: usually wooden cases, inner well protected.

Get A Quote

Contact

Welcome to contact us for a long term well business cooperations.

Address

No. 5, Taohuali, New & High-Tech. Development Zone, 450000, Zhengzhou, Henan Provience, P.R.China.

Contact

Attn: Chris Chyi (Sales Engineer.)

Mobile/Whatsapp/Wechat: +86-18637192800

Tel/Fax: +86-371-61310120

Email: sales@peaklandcn.com peaklandcn@gmail.com

Opening Hours:

Mo-Fr: 8:00-19:00

Sa: 8:00-17:00

So: closed